- Our productline

- Our technologies

- Ask a quote

Filter by attributes

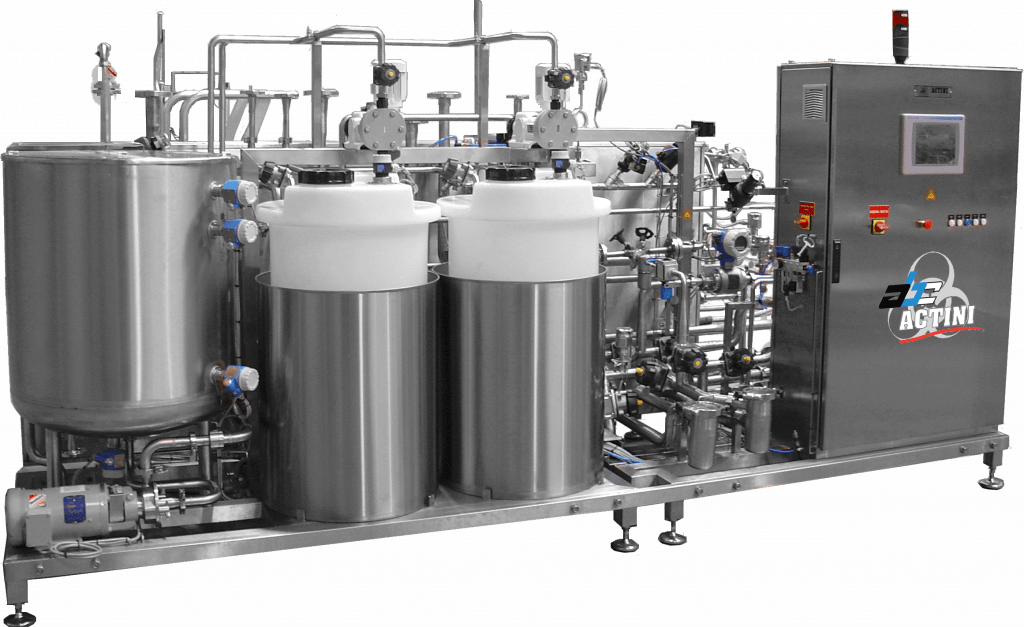

CYCLOBATCH

- Effluents BSL: 1-2-3-4

- Capacity: Up to 4,200 gallons per day

- Technology: Batch

- Utility: Steam

CONTINUOUS FLOW DECONTAMINATION SYSTEM

- Effluents BSL: 1-2-3-4

- Capacity: Up to 50,200 gallons per day and more

- Technology: Continuous flow

- Utility: Steam (or Electricity)

LAB CONTAINER

- Effluents BSL: 1-2-3

- Capacity: 40-foot high-cube shipping container

- Technology: Batch or Continuous Flow

- Utility: Electricity or Steam (autonomous)

-

Decontamination

- Configurable time/temperature treatment settings

- Batch or continuous units

- Electricity or steam-operation

- Patented and innovative technologies

- Guaranteed decontamination with treatment validation by temperature sensors or eddy diffusion (turbulence)

- Ensured effluent containment

-

Design

- Pre-engineered solutions with customizations to fit URS

- Designed for decontamination of BSL 1-2-3-4 liquid biowaste effluent

- Specific design for BSL 4 containment and ATEX requirements

- Energy recovery section: good for savings, good for the environment

- Reduced footprint

- Modular and upgradeable solutions

- Sanitization cycles

-

Automation

- Automatic operation

- Fully instrumented units for enhanced safety

- Monitored and recorded cycles

-

Advantages

- Homogeneity of the treatment

- Ideal to treat large volumes of biowaste effluent

- Reduced installation and commissioning time

- Short qualification times

- Compliance with strictest American decontamination standards

Contact our sales department

To receive more information about our products in the USA and Canada, please contact us.